Contract Development and Manufacturing (CDMO)

GMP manufacturing and quality control expertise

Introduction to GMP Manufacturing Facility

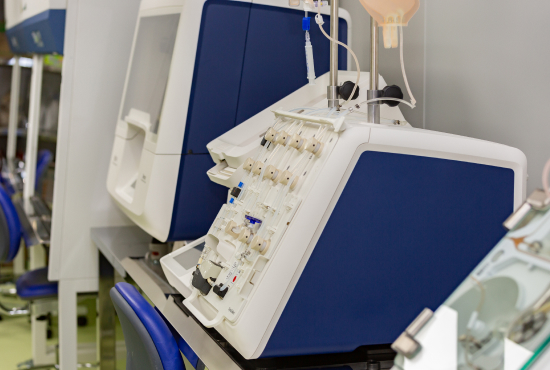

[GMP Facility 1] Cell Therapy

| Location |

Seoul, Gangnam-gu,

|

Area | 580m² | |

|---|---|---|---|---|

| CAPA | Production | 116 units (based on Cellstack containers) / 73,776㎠ (based on surface area) | ||

| Storage | 110,800 vials (vial-based) / 4,500 bags (bag-based) | |||

| Structure |

|

|||

| Application | Clinical-grade cell and gene therapies (Naïve / Pre-conditioned / Gene-modified MSC, T cell, NK cell) | |||

[GMP Facility 2] Cell & Gene Therapy

| Location | Hanam, Gyeonggi Province | Area | 3,443㎡ | |

|---|---|---|---|---|

| CAPA | Production | 198EA(based on Cellstack containers) / 125,928㎠ (based on surface area) | ||

| Storage | 260,800 vials (vial-based) / 10,800 bags (bag-based) | |||

| Structure |

|

|||

| Application | Clinical-grade cell therapies (Naïve / Pre-conditioned / Gene-modified MSC, T cell, NK cell) | |||

[Exterior view of GMP facility 1 & 2]

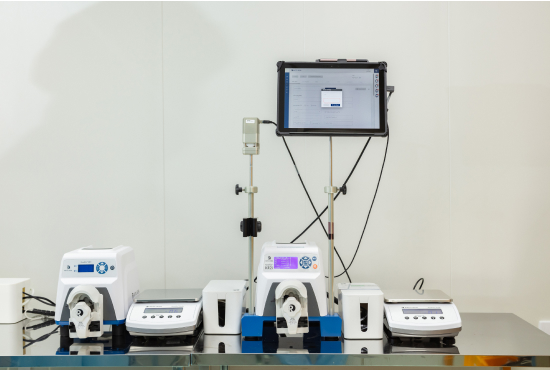

[GMP Facility 3] Gene Therapy

| Location | Hanam, Gyeonggi Province | Area | 1,161 m² | |

|---|---|---|---|---|

| CAPA | Raw Materials | 20 Lots/Year (1x10¹² vg/ml) | ||

| Finished Products | 20 Lots/Year (10,000 vials/year) | |||

| Structure |

|

|||

| Application | Clinical-grade gene therapies (Viral Vectors: Lentivirus, Adeno-associated virus, Adenovirus) | |||

| Key Features | Airborne Particle Control System, Separate Biopharmaceutical DP Production, Single-Use & Closed Systems | |||